What is cryo-EM?

Cryo-electron microscopy (Cryo-EM) is a cutting-edge imaging technique that has transformed the field of structural biology. Unlike traditional methods such as X-ray crystallography, which require crystallization of biomolecules, Cryo-EM enables scientists to visualize proteins, nucleic acids, and complex assemblies in their native states without crystallization. By rapidly freezing biological samples and imaging them under cryogenic conditions, Cryo-EM produces high-resolution three-dimensional reconstructions that reveal molecular details at near-atomic precision.

A key aspect of this technology is the use of cryogenic cooling, which preserves delicate biomolecular structures by preventing the formation of damaging ice crystals and reducing radiation damage during electron beam exposure. This is typically achieved with liquid nitrogen (LN₂, -196 °C / 77 K) or, in specialized cases, liquid helium (LHe, -269 °C / 4.2 K). Among these, liquid nitrogen is the most widely used due to its availability, cost-effectiveness, and excellent cooling efficiency.

The Role of LN2 in Cryo-EM

Liquid nitrogen plays a central role in cryo-electron microscopy, both during sample preparation and throughout the imaging process. Its primary function is to maintain biological specimens at cryogenic temperatures, ensuring structural preservation and minimizing the damaging effects of electron beam exposure. In practice, LN₂ is used at multiple stages of Cryo-EM workflows, including:

-

Cryo-EM relies on flash-freezing samples in a thin layer of vitrified ice to preserve their native structure.

-

LN₂ cools samples so rapidly that water molecules do not crystallize, forming amorphous ice instead.

-

Prevents ice crystal damage, which would distort biomolecular structures.

-

High-energy electron beams can destroy biological specimens.

-

Cryo-cooling with LN₂ slows down molecular movement, minimizing beam-induced damage.

-

Enables longer exposure times for better signal-to-noise ratios.

-

Thermal drift at room temperature can blur high-resolution images.

-

LN₂ cooling ensures thermal stability, improving image alignment and reconstruction accuracy.

-

Cryo-ET requires samples to remain frozen while tilted under the electron beam.

-

LN₂ cooling prevents sample dehydration and structural collapse.

Which Cryo-EM Steps Use Liquid Nitrogen?

- Cryo-EM Grid Preparation (Plunge Freezing)

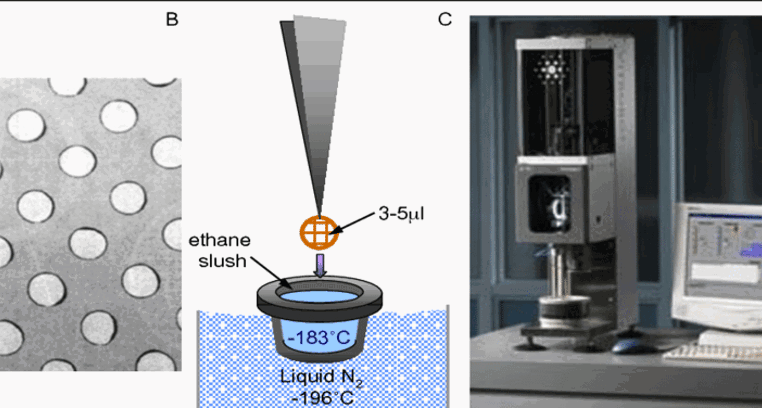

One of the most crucial steps in Cryo-EM is vitrifying biological samples on EM grids. During plunge freezing, a thin aqueous film containing biomolecules is applied to a grid and then rapidly plunged into liquid ethane (or propane) that has been pre-cooled by LN₂.

- Why not plunge directly into LN₂? Although LN₂ is much colder (-196 °C), its lower heat capacity and film-boiling effect (Leidenfrost phenomenon) make cooling less efficient. In contrast, liquid ethane (~-183 °C) offers much faster and more uniform cooling, ensuring proper vitrification without ice crystal formation.

- Role of LN₂: LN₂ serves as the cooling reservoir that keeps ethane at its cryogenic temperature, enabling reproducible vitrification across hundreds of grids.

A microfuidics based sample freezing method for cryo-electron microscopy - Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Cryo-EM-sample-freezing-A-Portion-of-a-Quantifoil-TM-holey-grid-Each-hole-is-about_fig1_237179540 [accessed 30 Sept 2025]

2. Cryo-Holders and Autoloaders

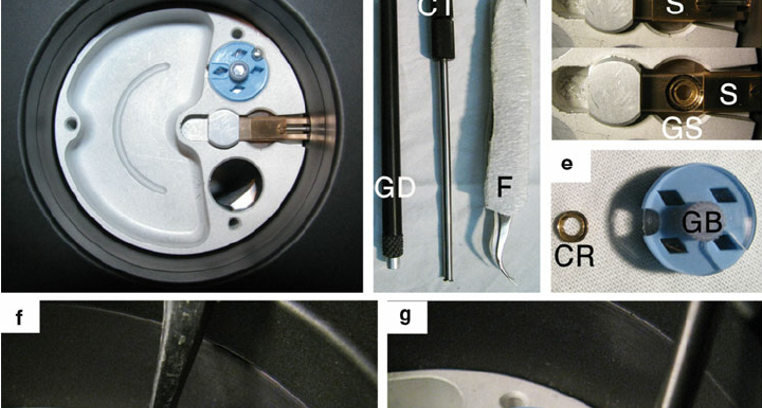

Once grids are prepared, they must be kept at cryogenic temperatures during transfer and imaging. Modern Cryo-EM microscopes use specialized cryo-transfer holders and automated loading systems.

- Cryo-holders: These devices maintain grids at ~-180 °C by being filled with LN₂, protecting samples from ice contamination during transfer into the microscope.

- Autoloaders: LN₂ cooling prevents condensation and maintains vitrified conditions inside the microscope column. Without LN₂, samples would rapidly warm, causing devitrification and structural loss.

Cryo-electron Microscopy of Vitreous Sections - Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Loading-a-grid-into-a-cryo-holder-a-Cryo-holder-CH-inserted-in-the-cryo-transfer_fig9_259395288 [accessed 30 Sept 2025]

3. Cryo-Stages in TEM/STEM

Inside the transmission electron microscope (TEM) or scanning TEM (STEM), stable imaging requires precise temperature control.

- LN₂-cooled stages: These minimize thermal drift, which can otherwise blur images at high magnifications.

- Closed-cycle cryocoolers: Some advanced systems are transitioning toward mechanical cooling solutions to reduce LN₂ handling. However, LN₂ is still commonly used for pre-cooling and as a backup to ensure stability and reduce contamination.

4. LN₂-Cooled Detectors (Direct Electron Detectors)

High-end direct electron detectors, such as the Gatan K3 or Thermo Fisher Falcon 4, sometimes employ LN₂ cooling.

- Purpose: Cooling the detector reduces thermal noise during long exposures, improves signal-to-noise ratios, and enhances detection efficiency for weak signals.

- Impact: This enables better dose efficiency and more accurate reconstruction of molecular structures at high resolution.

Best Practices for LN2 Use in Cryo-EM

- To prevent ice contamination, dry LN₂ gas purges are often used around the sample stage to keep moisture away. Vitrification within a glovebox is another effective approach, as it minimizes humidity exposure during sample preparation.

- Minimizing LN₂ boil-off is key for efficiency. Super-insulated Dewars with low evaporation rates reduce unnecessary loss, while automated refill systems such as the Leica EM GP2 plunge freezer help maintain consistent cooling without manual intervention.

- Temperature stability is essential for high-quality cryo-EM results. LN₂ levels should be monitored closely to prevent fluctuations, and pre-cooling holders before sample transfer helps avoid thermal shock to delicate specimens.

- Finally, safety must always be prioritized. Because of frostbite risks, cryo-gloves are necessary when handling LN₂. Proper lab ventilation reduces the danger of asphyxiation, and vented storage containers should be used to prevent pressure buildup.

Why Choose On-Site LN2 Generation?

Traditionally, labs have relied on bulk LN₂ deliveries, but on-site nitrogen generators are increasingly being adopted for Cryo-EM facilities. On-site LN₂ generation offers:

- Uninterrupted Supply – No risk of running out between deliveries, ensuring experiments aren’t delayed.

- Guaranteed Purity – On-site generation reduces contamination risks, providing consistent LN₂ quality ideal for sensitive cryo-EM applications.

- Improved Safety – Reduces handling of large pressurized LN₂ containers and minimizes transfer-related hazards.

- Sustainability – On-demand production lowers carbon emissions associated with trucking and storage.

- Operational Efficiency – Automated systems can integrate directly with plunge freezers and cryo-stages, ensuring steady LN₂ availability without manual intervention.

Liquid nitrogen is indispensable in Cryo-EM, enabling high-resolution imaging, sample vitrification, and radiation damage reduction. From plunge freezing to cryo-holder stabilization, LN₂ ensures that biomolecules remain in their native state for accurate structural determination. As Cryo-EM technology advances, innovations in cryogenics will further enhance efficiency and accessibility.

To maximize these benefits, many facilities are now turning to on-site LN₂ generation for a safer, more cost-effective, and uninterrupted supply. If you’re looking to explore how liquid nitrogen generators can support your Cryo-EM workflows and determine the best system for your lab, get in touch with us to discuss tailored solutions.

Web - Visit the Contact page

Email - sales@noblegencryo.com

Call Us On - +44 (0) 191 460 1177