1: What They Are & How They Work

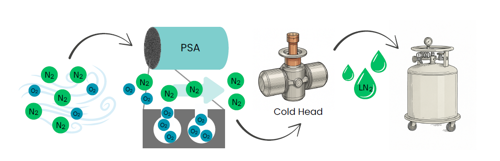

Liquid nitrogen generators produce nitrogen by separating it from ambient air using cryogenic technology, then cooling it to extremely low temperatures (-196°C).

There are different types of generators on the market, but the way they function is very similar, following the same steps from air compression to separation, purification, liquefaction and finally dispensing. You can read more about this process and the technology involved in each step in our article: How do liquid nitrogen generators work?

2: The Many Different Liquid Nitrogen Applications

The use of liquid nitrogen generators is widespread, from medical and pharmaceutical cyropreservation, to research labs, electronics manufacturing, dermatology and more. A lot of applications involve cryogenic freezing of samples or materials, allowing scientists to share knowledge and preserve key materials. Other important use cases include instrument and magnet cooling applications, in which detectors are cooled with liquid nitrogen, cryogenic milling of all kinds of materials, as well as radar calibration, semiconductor fabrication, dermatology and many more.

3: How Easy They Are to Use

If you thought operating a generator is a complicated process, you couldn't be more wrong. Noblegen's cabinet-based generators are very easy to use, with a touchscreen display that shows all important diagnostics in real time, so you can follow what is happening inside the generator. Dispensing through a hose or flask is a simple process that doesn't require special training (only the right PPE!).

Generating liquid nitrogen in-house is much more convenient than the administrative work, scheduling, and potential operational disruption caused by late deliveries. In addition, on-site generation lowers transportation and delivery costs, minimizes downtime, and offers long-term savings. Read more about the benefits of generating your own supply.

![]()

4: The Safety Aspect

On-site generation significantly reduces some of the major risks associated with deliveries. From high-pressure vessels to transport risks in badly ventilated areas, generators reduce the risks.

Built-in safety features, such as vacuum protection system, automatic standby, and emergency stop button reduce the potential for hazardous incidents. Noblegen generators instantly react to pressure or temperature changes, resulting in a system that's not only easy to operate, but safe and accessible to all users.

By generating only what's needed, when it's needed, the demand for bulk storage decreases (and gets stored safely inside the generator's dewar), enhancing overall site safety.

5: Sustainability

Have you ever thought about how the carbon footprint of your deliveries is affecting the environment? Cutting out road transport significantly decreases greenhouse gas emissions and energy input associated with bulk deliveries.

On-site generation is a greener alternative -regardless of your location-, but this change is especially influential for remote, off-grid and mobile applications, where constant fossil fuel-powered deliveries are polluting the planet.

Ready to Switch to On-Site Generation?

Contact our team today to learn how Noblegen’s advanced liquid nitrogen generators can transform your operations.

Request a free consultation with our team to start your journey toward smarter, greener liquid nitrogen generation.